Richard Tyler

The cladding used in the refurbishment of Grenfell Tower was never subject to legally required fire safety tests.

According to the London Times, no record of independent testing of the cladding/insulation system has been found by three separate investigations into the Grenfell fire, including the government’s own expert panel on fire safety, the Metropolitan Police and the Hackitt Review into building regulations.

The potential risk extends to 299 other high-rise buildings in England that use similar cladding and insulation, including at least nine hospitals, 160 social housing blocks, 31 student residences, 13 public buildings and 95 private residential blocks.

The Times quotes a source with knowledge of the investigations saying, “The question has to be asked is how on earth did this material come to be installed on all of those buildings. Somehow or other, those materials have got on to 300 buildings without any tests being done or test results being produced.”

The refurbishment of Grenfell Tower, in which 71 lost their lives in the June 2017 fire, was signed off by building control managers at the Royal Borough of Kensington and Chelsea council in 2016. However, if the report by the Times is correct, the cladding system never underwent mandatory safety testing.

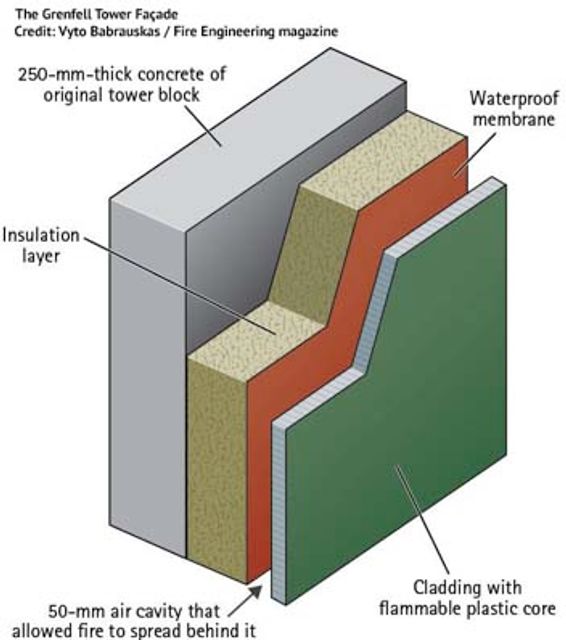

An illustration of the cladding on the Grenfell Tower

An illustration of the cladding on the Grenfell Tower

An article in Fire Engineering magazine, published for nearly 140 years to “provide training, education and management information for fire and emergency services personnel worldwide,” concludes that a major factor in the spread of the fire at Grenfell Tower was the large size of the air-gap between the external cladding and the insulation layer attached to the building façade.

According to the author, Vyto Babrauskas, a fire safety science expert and US delegate to the International Organisation for Standardisation (ISO) in the late 1990s and early 2000s—working to develop international standards for façade testing—the rapid spread of the fire at Grenfell was due to the “Schlyter effect.” This occurs in a fire when two panels on a building façade are separated by a small gap though which air can flow. As Babrauskas writes, “some materials may show limited burning and no significant flame spread when ignited as a single panel but yet show severe burning when a second panel is used.”

The effect was first demonstrated as long ago as 1939 by Ragnar Schylter, then head fire safety researcher at the Swedish National Testing and Research Institute. Babrauskas notes that although this effect is known to some fire scientists, it is “not generally well known in the fire safety area.”

“The best way to stop air flow is not have a gap in the first place. But if a gap has to exist for some moisture engineering purpose, then it is essential that it be less than 25mm or one inch and be fully fire stopped along the bottom and the sides by materials that cannot fail in the heat of the fire. If these precepts are not understood or are ignored, a bad situation can quickly be made much worse.”

Schylter had found that an air-gap of 25mm (1 inch) provided the optimum spacing to promote upward flame spread in a cavity. At 50mm (2 inches), the gap at Grenfell Tower was twice this width.

In the late 19th century, the first high-rise buildings had façades made of concrete, stone, brick, steel or glass. There was no need of a test for combustibility since these materials are inherently non-combustible. The situation changed 30 or 40 years ago with the introduction of “exterior insulation and finish systems (EIFS).” These are generally cheaper and often employ combustible materials with only a thin protective aluminium skin, which can soon melt in a fire. Non-combustible insulation alternatives, such as mineral wool, are available, but cost more.

The existing fire testing regimes for such cladding systems are generally inadequate, according to Babrauskas. In the case of Grenfell Tower, he comments that “even a novice fire safety functionary should have questioned a 150-mm (six-inch) layer of plastic foam,” used as insulation, adding that although it ostensibly carries the “best flame spread rating in the UK testing methodology” the “UK system for flame spread classification does not do an acceptable job of classifying foam materials.”

Research carried out earlier by Canada’s National Research Council (NRC) into the Schylter effect indicated that “the most minimal levels of combustibility would suffice to create a disaster when a cavity is created in a wall, especially one twice the width of the maximum 25-mm gap found acceptable by the NRC researchers.”

A tall façade using a combination of combustible materials, such as plastic and insulation foam, together with an air gap is, in Babrauskas’ view, “a design that trifles with the public safety.”

After the Grenfell Tower fire this is incontestable. For the sake of saving a few thousand pounds, an inherently unsafe form of cladding was used on a building without a proper fire warning or sprinkler system, and with inadequate escape routes.

Culpability extends from those responsible for proposing such cladding, to the local authority for signing off on its use, and the building contractors for fitting such dangerous materials. The lack of a rigorous testing regime, despite known contributing hazards such as the Schylter effect, points to a criminal conspiracy at the heart of what are supposedly called “building standards.” These exist primarily not for the protection of the public, but to enable the use of the lowest cost materials and hence the greatest profits for the construction giants and property speculators.

No comments:

Post a Comment